- Home

- Products

- FY-ROB Robotic System

- FY-ROB Series Robotic&Automatic System

Products

FY-ROB Robotic System

Beverage & Food & Pharma Packaging Machine

High Speed Series Overlapping

Counting, Grouping

Flow Wrapper Packaging

L-Type Packaging

Carton/Tray Wrapper & Wraparound Case Packer

Carton/Tray Wrapper Case Packer

Tapes Packaging Solution

Automatic Shrink Sleeve Labeling Machine

Products

Robotic Automation System –

- Pick-and-Place System

- Delta Robot

- Robotic Palletizing System

Robotic & Automation System

We provide the latest and most versatile robotic systems. Our multi-axis robots are suitable for various types of product gripping and handling, with a focus on the food and beverage industry.

As a system integrator, we offer complete automation integration for pick-and-place, palletizing, and end-of-line logistics systems. We also deliver simple, universal, and easy-to-maintain solutions. Most importantly, our factory automation systems are cost-effective and significantly reduce production expenses.

Pick & Place System

The pick-and-place system is capable of transferring products to designated locations, suitable for continuous path applications; it performs tasks such as picking, boxing, loading, and unloading in specific areas.

Customized grippers can handle products of various types and shapes, such as bottles, small pouches, sachets, individually packed items, display cartons, tubes, etc.

The number of items picked per cycle can be configured based on the production line capacity.

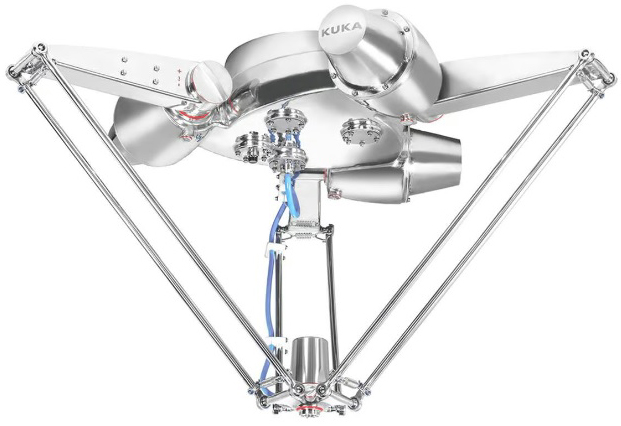

Delta Robot

The FY-ROB Delta series robots are specially designed for pick-and-place tasks, meeting the highest standards of hygiene and safety, ideal for high-output and small-item industries such as meat, biscuits, chocolate, dairy products, ready-to-pack foods, canning, or other product sorting operations.

FY-ROB Robotic Palletizer System / Palletizing System

The FY-ROB robotic arm meets all modern automation requirements, with minimal space needs, shorter cycles, and maximum availability. The palletizing arm system features 5 or 6 axes, offering flexible operation and highly durable stacking solutions. With a load capacity of 3 to 500 kg (including grippers), it can handle about 3,000 cartons per hour. Providing customized and effective solutions to meet customer needs is our core goal. The system supports 5 to 7 cycles per minute or faster, and the arm can be equipped with various types of end-of-arm tools (EOAT), such as claws, suction cups, clamping devices, etc.

FY-ROB Series Robotic System / Features

- Human-machine interface operation.

- Standalone floor-mounted electrical control box design.

- Large allowable inertia for heavy-duty handling tasks.

- Automatic error messaging for easy troubleshooting.

- Capable of servicing multiple production lines with large working ranges.

- Operable in both harsh environments and conventional workshop settings.

- Proven, reliable servo drives ensure maximum uptime and productivity.

Technical Specifications

|

Specifications

Robot Type

|

Articulated Robot | Delta Robot |

|---|---|---|

| Arm Applications | Pick & place, stacking, education, advertising display, and more | High-speed pick & place |

| Payload Capacity | Up to 1500 kg | 1~30 kg |

| Production Speed | Up to 1,200 cycles/hour | Up to 9,000 cycles/hour |

| End Effectors | Grippers, suction cups, clamping tools, etc. | |

| Product Types | Applicable to all product types | |

| Stacking Method | Flexible from single box to full layer based on production speed |

◎ Machine dimensions are for reference only. Final design may vary.