- Home

- Products

- Beverage & Food & Pharma Packaging Machine

- High Speed Series Overlapping

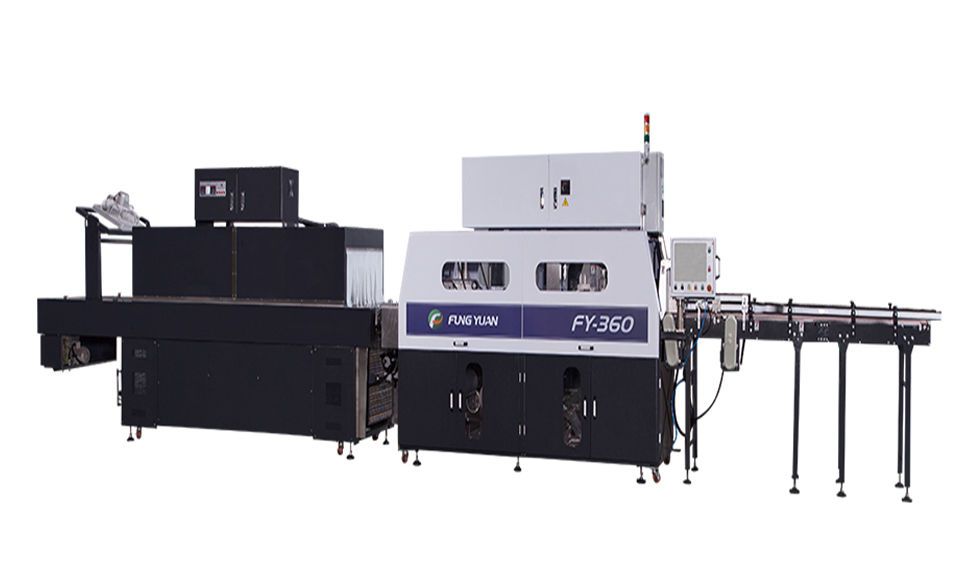

- FY-360&FY-360LLMT High Speed Overlapping Packaging Machine

Products

Products

FY-ROB Robotic System

Beverage & Food & Pharma Packaging Machine

High Speed Series Overlapping

Counting, Grouping

Flow Wrapper Packaging

L-Type Packaging

Carton/Tray Wrapper & Wraparound Case Packer

Carton/Tray Wrapper Case Packer

Tapes Packaging Solution

Automatic Shrink Sleeve Labeling Machine

Products

Bottom-overlapping shrink film packaging, suitable for production lines operating at 400–500 BPM.

Features

-

Packaging Speed:

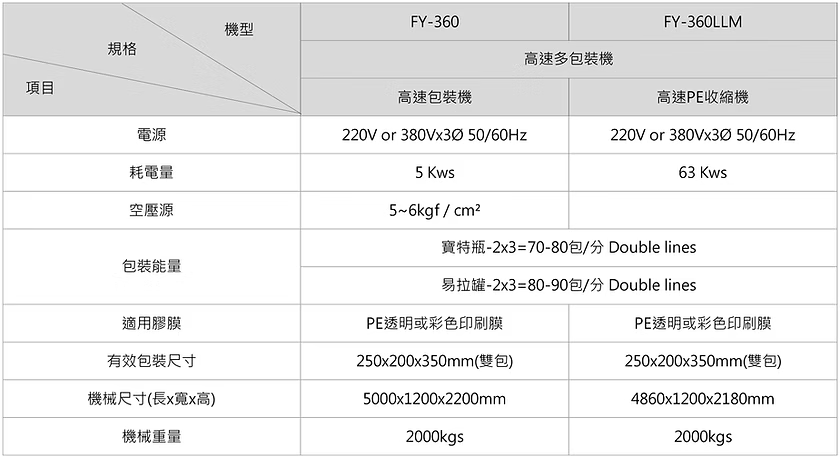

A/ For aluminum can configurations such as 2x2, 2x3, and 3x4, the 2x2 and 2x3 formats can reach up to 80 packs per minute.

B/ For PET bottles (500cc–1500cc, including 5-claw bases), 2x2 and 2x3 formats can reach up to 65 packs per minute. High-speed operation is ideal for fast production lines. - Infeed Method:

Vertical infeed with automatic sorting, synchronized single and dual pack actions. Perfect for integration with existing production lines. - Shrink Film Wrapping Style:

Bottom-overlapping design with no seal lines, delivering a clean and aesthetically pleasing package. Eliminates common sealing line cracking issues seen in traditional shrink wrap. - Film Material:

PE single-roll film; compatible with both transparent and color-printed film with registration marks.

(This machine is especially suited for PE printed film, adding promotional and marketing value to the product.) - Control System:

Servo-driven control system for smooth and reliable operation. User-friendly HMI interface for easy control and setup. - Chain-driven linkage with plastic steel mesh conveyor for efficient film wrapping without the need for pushers. Fast, simple, and highly accurate packaging results. Easily integrates into existing production lines.

- Heat shrink tunnel with uniform thermal radiation. The conveyor is made of stainless steel mesh, offering durability and long service life.

- Equipped with specialized air circulation inside the shrink tunnel for printed films. Adjustable airflow and direction ensure smooth and uniform shrink results for both printed and transparent films.

- Diverse packaging configurations to meet retail packaging demands. Maintains product quality, reduces energy consumption, and enhances profitability.

- Safety Design:

Enclosed safety guards around the exterior. Built-in safety detection systems include no-film detection, overturned container detection, print-mark tracking via sensor, and integrated alarm system. - Easy inline installation and compact design make this machine the ideal packaging solution for GMP-certified factories.

- Note:

Different product sizes require switching to matching molds. The machine includes one standard mold set. For square or flat bottles, a lane divider mechanism must be added at the infeed section.

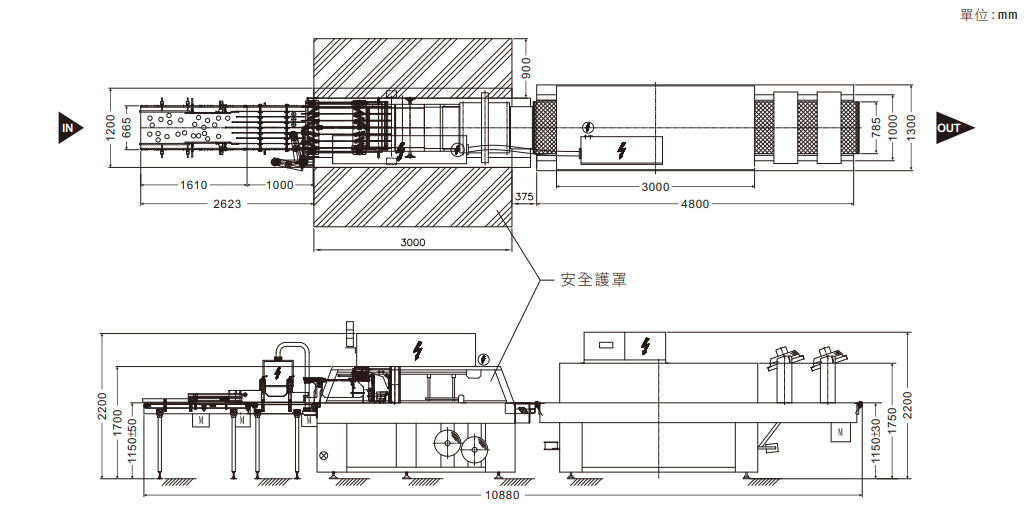

Machine Dimensions

Machine Specs

◎ Packaging speed depends on product size, packaging style, and the stability of the product on the conveyor.

◎ Machine dimensions are for reference only; please refer to the actual design.