- Home

- Products

- Tapes Packaging Solution

- FASP-6020-2 PVC & OPP Tapes Accounting Grouping Sealing and Shrink Packaging Machining Machine

Products

Products

FY-ROB Robotic System

Beverage & Food & Pharma Packaging Machine

High Speed Series Overlapping

Counting, Grouping

Flow Wrapper Packaging

L-Type Packaging

Carton/Tray Wrapper & Wraparound Case Packer

Carton/Tray Wrapper Case Packer

Tapes Packaging Solution

Automatic Shrink Sleeve Labeling Machine

Products

Sleeve-type dual-side sealing packaging method with an output capacity of approximately 5–13 packs/min.

Features

- Carefully engineered for fully automatic feeding to packaging completion, significantly saving labor.

- Easy mechanical adjustments to accommodate product variations.

- Flexible packaging configurations support dual rolls in sets of 6, 8, 10, or 12 rolls.

- Packing material uses non-toxic, eco-friendly PE shrink film.

- Applicable for PVC electrical tape, OPP tape, and flat or round-shaped products.

- Product logos are oriented outward for neat and uniform presentation.

- Operated via HMI touch screen, intuitive and user-friendly.

- Digital temperature controller allows precise sealing temperature settings and adjustments.

- Best suited for integration with computer-based operations or PLC-controlled production lines.

Machine Dimensions

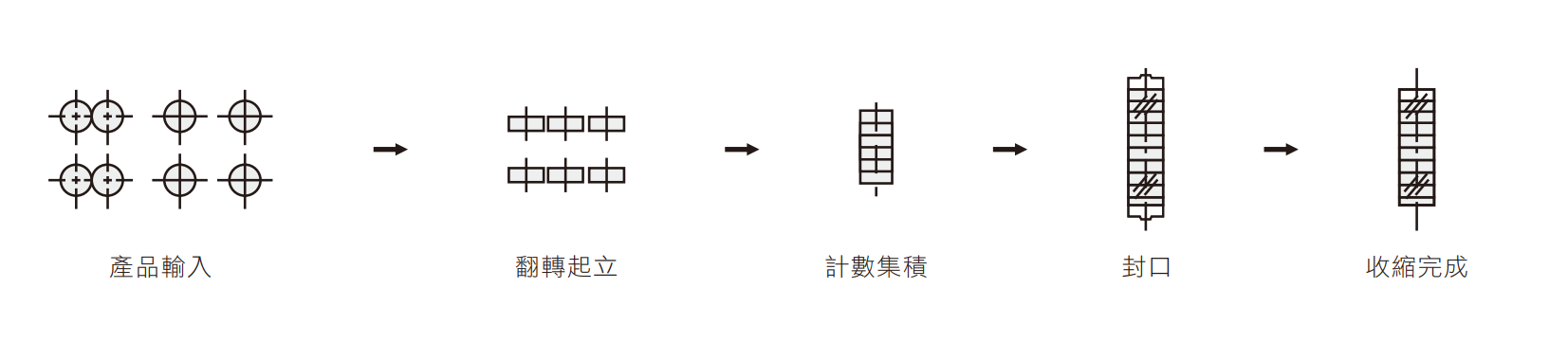

Packaging Flow Chart

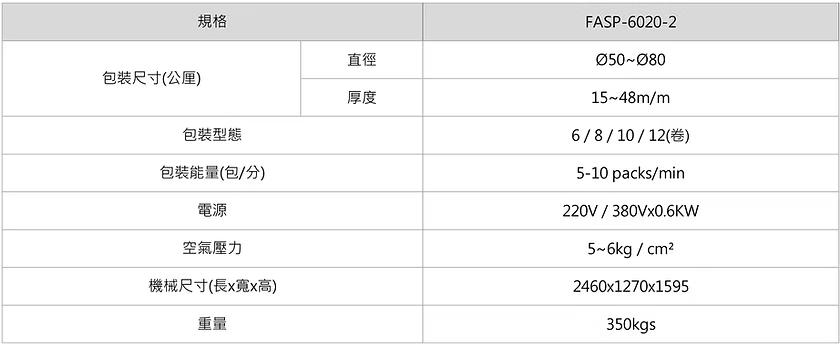

Machine Specs

◎ Packaging speed depends on product size, packaging style, and the stability of the product on the conveyor.

◎ Machine dimensions are for reference only; please refer to the actual design.

FM-4525 Shrink Machine / Features

- Digital temperature controller for accurate adjustment of internal oven temperature.

- Maintains product integrity, reduces energy consumption, and boosts profitability.

- Shrink tunnel equipped with circulating fan motor ensures uniform hot air; conveyor uses rollers for durability and adjustable speed.

- Rollers are covered with heat-resistant silicone or fiberglass sleeves to prevent film adhesion.

FM-4525 Shrink Machine / Specs