- Home

- Products

- Beverage & Food & Pharma Packaging Machine

- High Speed Series Overlapping

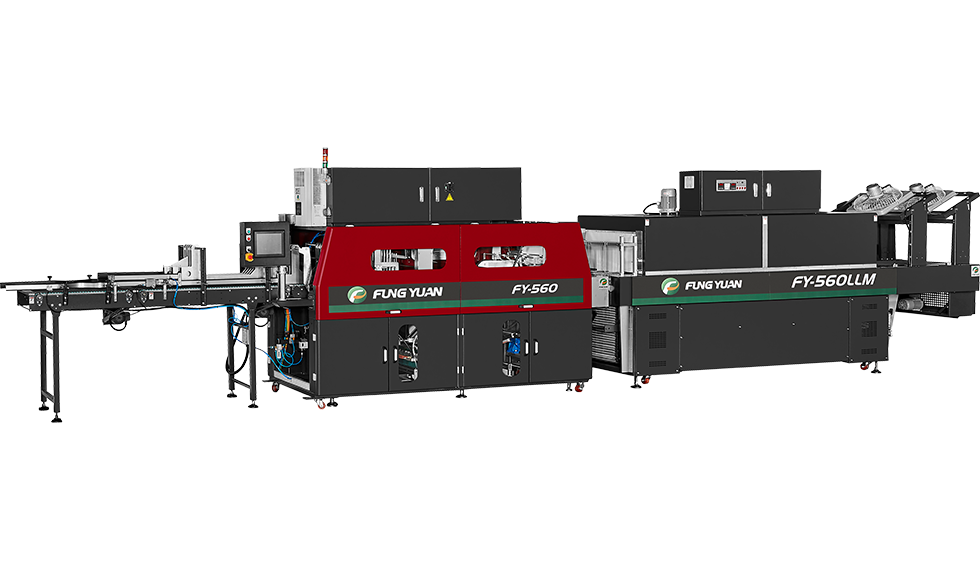

- FY-560&FY-560LLMT High Speed Overlapping Packaging Machine

Products

Products

FY-ROB Robotic System

Beverage & Food & Pharma Packaging Machine

High Speed Series Overlapping

Counting, Grouping

Flow Wrapper Packaging

L-Type Packaging

Carton/Tray Wrapper & Wraparound Case Packer

Carton/Tray Wrapper Case Packer

Tapes Packaging Solution

Automatic Shrink Sleeve Labeling Machine

Products

Bottom-overlapping shrink film packaging, suitable for production lines operating at 500–600 BPM.

Features

-

Packaging Speed:

A/ For aluminum can types (e.g., 2x2, 2x3, 3x4), up to 120 packs per minute for 2x2 and 2x3 formats.

B/ For PET bottles (500cc–1500cc, including 5-claw bases), up to 100 packs per minute. Suitable for high-speed production lines. -

Product Infeed Method:

Vertical infeed with automatic sorting, synchronized single and double pack operations. Ideal for integration with production lines. -

Shrink Film Wrapping Method:

Bottom-overlapping design with no sealing lines for a sleek appearance. This advanced packaging eliminates seal-line cracking common in traditional shrink wrapping. -

Shrink Film Material:

Single-roll PE film; both transparent and printed films with positioning marks are supported. Ideal for printed films to boost product appeal and promotional effect. -

Control System:

Servo-driven with smooth motion. User-friendly human-machine interface (HMI) makes operation simple. - Chain-driven linkage with plastic mesh conveyor for film feeding—no need for pusher arms. High-speed, simple, precise, and efficient for neat packaging.

- Shrink tunnel features uniform thermal radiation and durable stainless-steel mesh conveyor.

- Equipped with adjustable airflow and wind direction for shrink tunnel, ensuring excellent appearance for both printed and clear film-wrapped products.

- Diverse packaging formats to meet retail demands while preserving product quality and saving energy—boosting profitability.

-

Machine Safety Design:

Equipped with safety doors and guards. Built-in safety detection functions include film-out detection, overturned container detection, and print-mark tracking via sensors with alarm system integration. - Easy inline installation with a streamlined design—an ideal packaging solution for GMP-compliant factories.

-

Note:

Packaging of different size formats requires mold replacement. The machine includes one mold set by default. For square or flat bottles, additional product sorting units are required at the infeed section. - Fully integrated Allen Bradley PLC control system with HMI and servo components also from Allen Bradley.

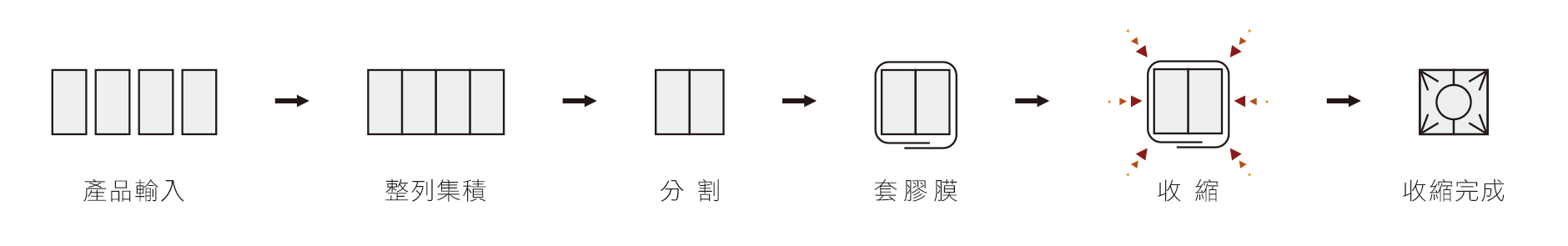

Packaging Flow Chart

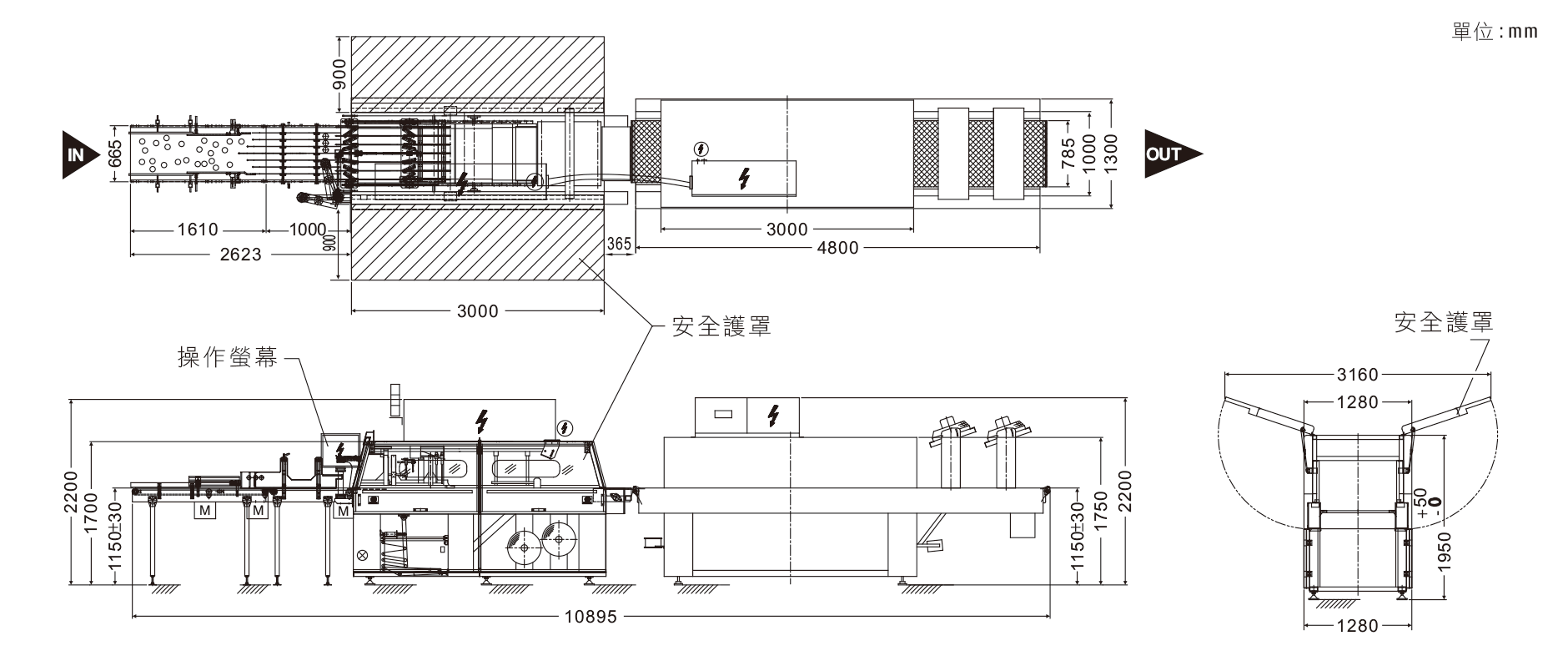

Machine Dimensions

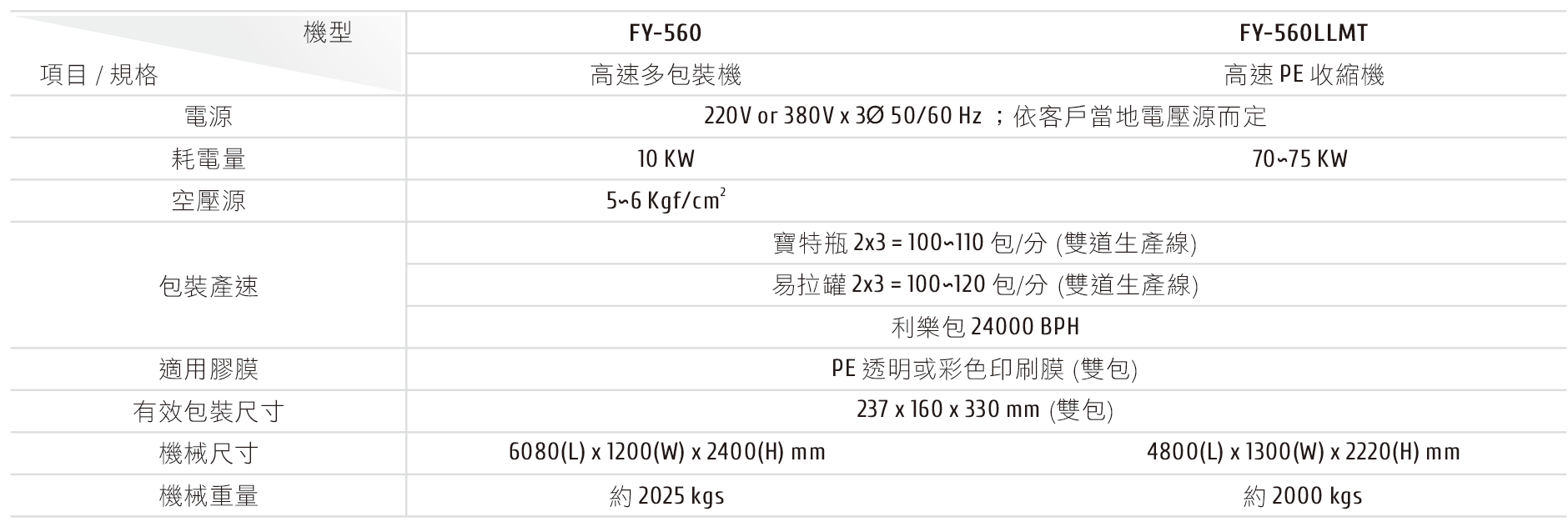

Machine Specs

◎ Packaging speed depends on product size, packaging style, and the stability of the product on the conveyor.

◎ Machine dimensions are for reference only; please refer to the actual design.